8 Common Misuses of Hydraulic Piston Pumps – The Consequences Are More Serious Than You Think!

Апрель 24, 2025

Hydraulic Pumps: How Long They Last, Why They Fail, and How to Prevent It

Май 18, 2025Common Faults and Troubleshooting Methods of Excavator Hydraulic Pumps

Keywords: excavator hydraulic pump failure, hydraulic system troubleshooting, low hydraulic pressure, excavator repair, hydraulic pump diagnosis

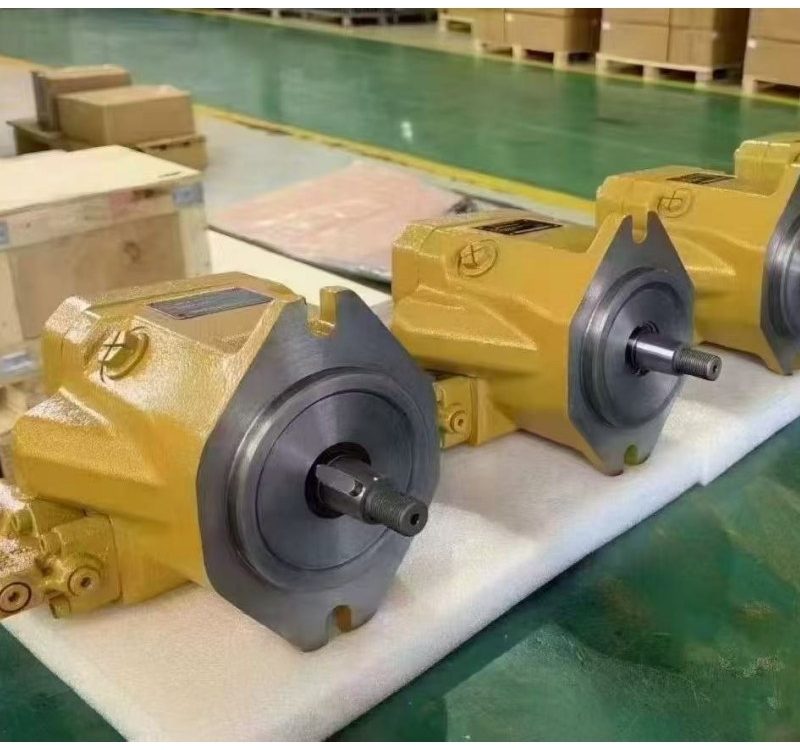

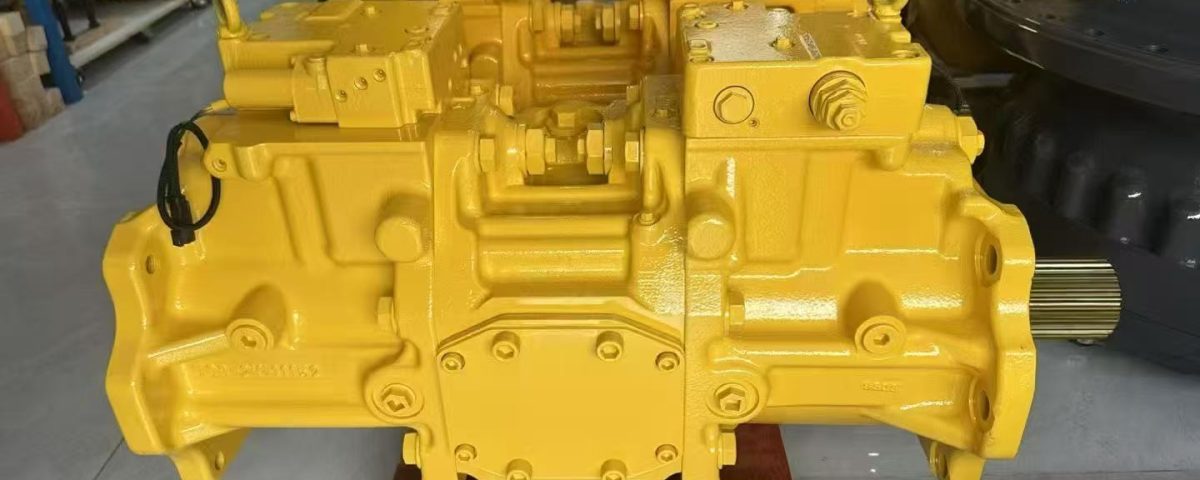

The hydraulic pump is the heart of an excavator’s hydraulic system. Its performance directly affects the machine’s efficiency and reliability. Due to high workload and harsh conditions, hydraulic pumps are prone to various failures if not properly maintained. This article provides a comprehensive guide to the diagnosis and repair of common hydraulic pump problems, covering fault identification, diagnostic methods, and effective solutions.

1. Common Hydraulic Pump Failures in Excavators

1.1 Engine Speed Drops

If the engine RPM drops significantly, begin by checking the engine’s output power. If it’s below the rated value, the issue may be due to:

- Poor fuel quality or low fuel pressure

- Incorrect fuel injection timing or valve clearance

- Air leaks in the intake system

- Malfunctioning turbocharger or exhaust restrictions

- Faulty brake control system

If the engine is functioning correctly, investigate the pump control system and the electrical and hydraulic circuits for faults.

1.2 Sluggish Operation Speed

Slow working speed is typically caused by:

- Internal wear in the hydraulic pump (e.g., pistons, cylinder block, valve plate)

- Hydraulic oil leakage within the system

- Insufficient flow output and elevated oil temperatures

These issues often require a complete pump overhaul and replacement of worn components.

1.3 Weak Excavation Force

There are two main scenarios of low digging power:

- The engine is not under load, and the machine feels light and unresponsive.

- The engine bogs down or stalls when the boom or arm reaches the end of stroke, indicating excessive system pressure or incorrect relief valve settings.

2. Diagnostic Methods for Hydraulic Pump Failures

Several tools and techniques can help quickly and accurately diagnose issues in excavator hydraulic pumps:

2.1 Quick Oil Analysis

This method assesses oil degradation based on changes in its dielectric constant. By analyzing hydraulic oil condition on-site, potential failures caused by poor oil quality can be identified early, helping prevent system damage and optimize oil change intervals.

2.2 Hydraulic System Tester

This tool measures actual flow output at different pressure conditions:

- Install the tester on the pump’s high-pressure line using a bypass method.

- Run the pump at rated speed and measure the flow at no load.

- Gradually apply pressure until reaching rated system pressure, and compare flow rate.

- A 25% drop in flow indicates pump degradation; a 50% drop confirms serious pump failure requiring disassembly.

2.3 Noise Meter

Normal noise levels should not exceed 105 dB. Excessive noise may indicate:

- Misalignment between pump shaft and motor

- Air entrainment in the system

- Severe internal wear of pump components

2.4 Temperature Sensor

By comparing the pump housing temperature and hydraulic oil temperature:

- A difference over 5°C suggests low mechanical efficiency

- A 10°C+ difference with normal oil quality and pressure points to increased internal leakage or worn parts

2.5 Pressure Gauge Monitoring

Although most pumps are pressure-compensated, abnormal gauge needle behavior (fluctuations over ±200 kPa or sluggish movement) may signal a malfunction or pressure instability.

3. Causes and Remedies for Common Hydraulic Pump Issues

3.1 Pump Not Drawing Oil

Possible causes and solutions:

- Reversed inlet/outlet ports – Reconnect according to the manual

- Oil too thick – Use hydraulic oil with the correct viscosity

- Cold oil – Warm up the system to operating temperature

- Blocked suction pipe or clogged filter – Clean or replace as needed

- Air leak in suction pipe – Check and reseal all joints

- Poor pump priming or small displacement pump – Pre-fill pump with oil

3.2 Insufficient Flow Output

Causes and troubleshooting tips:

- Low engine speed – Adjust to rated RPM

- System leakage – Locate and repair leaking joints or seals

- Loose pump cover bolts – Tighten all bolts

- Low oil level in tank – Refill to the proper level

- Air leaks in suction lines – Inspect and reseal fittings

Conclusion: Proactive Maintenance Prevents Costly Downtime

The excavator hydraulic pump plays a critical role in the overall performance of the machine. Regular monitoring through oil analysis, flow testing, temperature checks, and noise level assessments helps identify issues early. Proper diagnosis and timely maintenance not only extend equipment lifespan but also enhance job site productivity.

Need professional guidance on hydraulic pump repair or replacement? Contact our technical support team for personalized solutions.